Abstract

There was not only one steel primer used on WTC tower structural steels, but at least one other primer:

LaClede Standard Primer is a zinc-free paint formulation with which the floor joists of the twin towers were painted.

The painted area of these LaClede-painted floor joists in both towers was roughly 600,000 m2 while Tnemec is only known to have been specified for about 400,000 m2 of perimeter column surface. For the rest of the structural steel – core columns, hat truss and others, a total of 300,000 m2 the primer used isn't known.

Claims that Niels Harrit proved that some red-gray chips in the WTC dust are not WTC primer are basing this claim on the FALSE assumption that Tnemec was the only primer used. In fact, I will show that the chips that Harrit proved to not be Tnemec look very much like LaClede Standard Primer.

Introduction

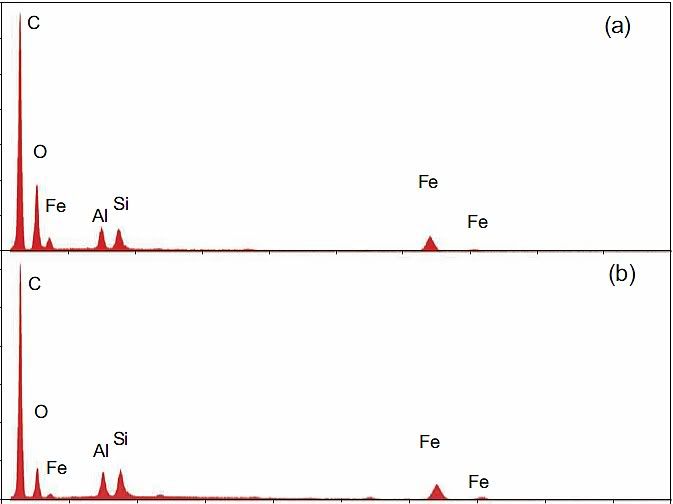

Back in May 2009, Niels Harrit wrote “Why The Red/Gray Chips Are Not Primer Paint” [1]. In it, he shows the composition of Tnemec Red, which has, among others, Zinc Yellow as it's main pigment. He then shows, in his Fig. 5, the XEDS spectra of the red layers of four red-gray chips labeled (a)-(d) from WTC dust, which he and 8 others had characterized in a paper published in April 2009 [2]. Result: Since Chips (a)-(d) contain no Zn, they can't be Tnemec. I agree with this finding – these four chips indeed are not Tnemec.

But Tnemec wasn't the only steel primer used in the WTC! As far as is known, Tnemec was the specified primer for the WTC perimeter columns[3].

At least one other primer has been applied to WTC steel: LaClede Steel Company, manufacturer of the floor trusses [4], used their own shop primer, or LaClede Standard Primer with the following composition [5]:

Pigment: 28.5% by weight

Iron Oxide: 55%

Aluminium Silicate: 41%

Strontium Chromate: 4%

Vehicle: 71.5%

Epoxy Amine and other: 100%

I find this false claim, that there was only one primer (Tnemec) used in the WTC towers, quite often in recent articles by people who want to defend Harrit e.al.'s claim that the red-gray chips are somehow nano-thermitic, for example at AE911T [6a]. These authors need to understand that they err: They have so far overlooked LaClede Standard Primer!

LaClede Standard Primer

The above formulation of LaClede Standard Primer can be broken into chemical elements, with a few reasonable assumptions:

“Iron oxide” is hematite, chemical formula Fe2O3, a red pigment. Hematite pigments are bright red at particle sizes between 100 and 300 nanometers, and in that size it is universally used in all kinds of paints.

“Aluminium Silicate” is kaolin, chemical formula Al2Si2O5(OH)4, a clay mineral very commonly used in paints to control gloss consistence. Kaolin appears naturally in platetelets some micrometers across and some tens of nanometers thick, which tend to stack.

The cured epoxy vehicle is polymeric and it is difficult to give a sum chemical sum formula, but it is dominated by carbon (C, 68% by weight), oxygen (O, 13%), hydrogen (H, 9%) and nitrogen (9%)

With these chemical formulas, I computed the elemental composition of LaClede Standard Primer:

C: 48% by weight

O: 21%

Fe: 11%

H, N: 7% each

Si: 2.5%

Al: 2.4%

Sr: 0.5%

Cr: 0.3%

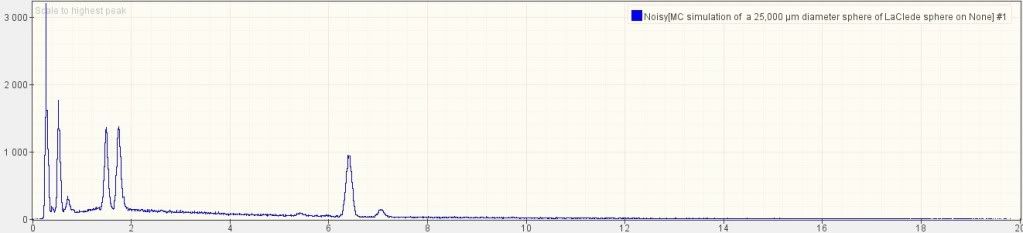

Using DTSA-II, a free multiplatform software package for quantitative x-ray microanalysis [7], I simulated a bulk sphere with the above chemical composition, using the same 20 keV that Harrit e.al. used:

The five larges peaks are, from left to right: C, O, Al, Si and Fe. Note the relative height: C is nearly twice as high as O; O is higher than than Al and Si; Al and Si are nearly equal; Fe is perhaps 70% of Si. Note that there is a small bump for Cr (chromium) at 5.4 (keV) on the x-axis, but none for Sr (strontium). The reason why strontium is invisible is that its main peak would be nearly exactly where the Si peak is, so it is hidden under the much larger Si signal.

We have estimated that the total painted surface area of the LaClede floor joists was about 600,000 m2 in both towers combined, or 50% more than the surface area of the exterior columns that were painted with Tnemec.

Discussion

Compare the XEDS graph of LaClede primer with Harrit's chips (a)-(d):

Now notice: C is again the highest peak by far, O is second in three of the four chips. Al and Si are nearly the same, Fe is typically about 70% of Si. And there is a small bump at 5.4 keV in chips b and d, which is chromium!

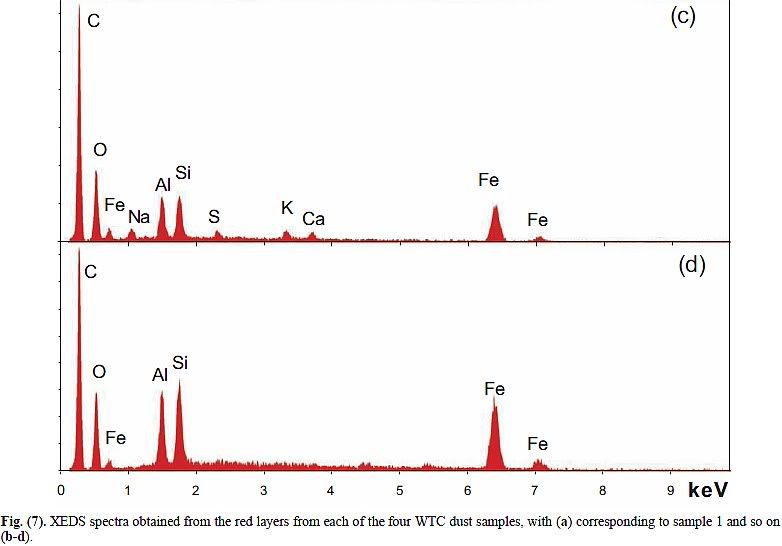

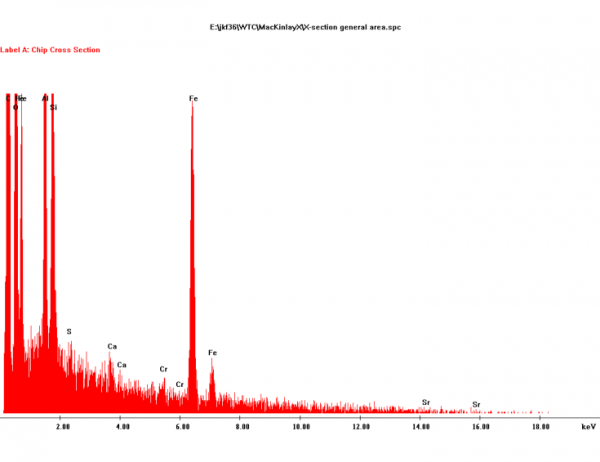

In [1], Harrit presents a more detailed XEDS graph for chip (a):

Do you see how Harrit has detected Cr (chromium) and even Sr (strontium) in trace amounts? Yep, there are also signals for S and Ca. Perhaps a tiny inclusion of gypsum, but I wouldn't bet on that.

Conclusion

I have shown that Harrit's argument, re-gray chips (a)-(d) can't be primer because they are not consistent with Tnemec, falls flat on its face, because Tnemec was not the only primer used on WTC steel. Another primer that must be considered is LaClede Standard Primer, and there could be even other primers of which no documentation seems to exist (we don't know for example which primer, or primers, was painted on the core columns and beams).

I have further shown that the XEDS spectra of chips (a)-(d) are very much consistent with the the paint formulation of LaClede Standard Primer.

I call on all honest and science-minded people in the 9/11 Truth Movement to reject Harrit's claim that chips (a)-(d) can't be primer as premature and consider LaClede Standard primer as a possible source for some of the red-gray chips. Tnemec may be another such source of other chips; in fact it seems that the MEK-soaked chip in [2] is consistent with Tnemec, as I have shown in another post [8] – this MEK chip can't possibly be identical with chips (a)-(d)! [9].

I further call on all students of [2] to realize that Harrit e.al. have analysed several different kinds of red-gray chips, and not pretend they are all basically the same.

References

[1] Niels H. Harrit: Why The Red/Gray Chips Are Not Primer Paint. Open Letter, May 2009

[2] Niels H. Harrit, Jeffrey Farrer, Steven E. Jones, Kevin R. Ryan, Frank M. Legge, Daniel Farnsworth, Gregg Roberts, James R. Gourley and Bradley R. Larsen: Active Thermitic Material Discovered in Dust from the 9/11 World Trade Center Catastrophe. The Open Chemical Physics Journal, 2009, 2, 7-31

[3] Carino, N. J.; Starnes, M. A.; Gross, J. L.; Yang, J. C.; Kukuck, S. R.; Prasad, K. R.; Bukowski, R. W.: Passive Fire Protection. Federal Building and Fire Safety Investigation of the World Trade Center Disaster (NIST NCSTAR 1-6A). 2005. Page 87: “...Series 10 Tnemec Prime (99 red), which is the primer that was specified for the exterior columns”

[4] Luecke, W. E.; Siewert, T. A.; Gayle, F. W.: Contemporaneous Structural Steel Specifications. Federal Building and Fire Safety Investigation of the World Trade Center Disaster (NIST NCSTAR 1-3A). 2005. Table 3-5, p. 21

[5] Gross, J. L.; Hervey, F.; Izydorek, M.; Mammoser, J.; Treadway, J.; Fire Resistance Tests of the Floor Truss Systems. Federal Building and Fire Safety Investigation of the World Trade Center Disaster (NCSTAR 1-6B). 2005. Appendix B, p. 157 of the PDF

[6a] AE911Truth Staff: FAQ #7: Aren’t the Red-Gray Chips Identified in the WTC Dust Merely Primer Paint from the WTC Steel Structural Elements?. Architects & Engineers for 9/11 Truth, 2012/03/15. Retrieved 2012/03/16

[7] Chuck Fiori, Carol Swyt-Thomas, and Bob Myklebust: DTSA-II Desktop Spectrum Analyser. Retrieved 2012/03/15

[8] Oystein: Steven Jones proves primer paint, not thermite. 2011/03/31

[9] Oystein: Why red-gray chips aren't all the same. 2012/03/14

'Do you see how Harrit has detected Cr (chromium) and even Sr (strontium) in trace amounts? Yep, there are also signals for S and Ca. Perhaps a tiny inclusion of gypsum, but I wouldn't bet on that.'

ReplyDeleteCan you not tell the difference between contaminated chips and the ones that have been cleaned?

- the washed chips do not match any of the paints that you suggest. None of your paints are explosive either for that matter.

“Aluminium Silicate” is kaolin, chemical formula Al2Si2O5(OH)4,

But Harrit demonstrated that (1)the silicon is not chemically bound to the al, therefore it cannot be al silicate. - (2)is is also shown that there is elemental al present.

There is no point debating with people like you - I could just as well try to debate Creationists.

To Anonym:

ReplyDeleteSigh...

How many dioptries do you have? You really do not see ANY resemblance of XEDS spectra of Bentham chips (a) to (d) and simulated spectra of Laclede paint, depicted above? Unbelievable:o)

Where did you get some data that any of the Bentham chips was explosive???

Harrit demonstrated (not really convincigly) that only in so called MEK chip (soaked in MEK) silicon was not bound to aluminum Al, which is fully expected, since this chip was particle of Tnemec primer which contained several silicon and aluminum paint pigments; they can separate during soaking and they are naturally separated even before soaking.

MEK chip was apparently different paint (Tnemec paint) than chips (a) to (d) (Laclede paint), that is what this blog is about now.

Thanks, Anonymous, for your comment, and Ivan for the reply. I think you are spot on, Ivan. One more thing:

ReplyDelete"Can you not tell the difference between contaminated chips and the ones that have been cleaned?"

Harrit's XEDS graph with the strontium and chromium signals is from the fresh, newly-exposed clean surface of a chip they just cut in half. So that is a pretty uncontaminated surface, and Sr and Cr are likely in fact an ingredient of the red layer, not surface contamination. Sorry if that was not clear from my articel.

You still do not understand what you are talking about:

ReplyDelete1. Your own analysis of composition by weight of your primer paint and Basile´s samples debunks your work. The only match is amount of oxygen, thats it. All the others are WAY OFF, especially Iron. Basile´s chips cannot be this primer. Better luck next time.

2. Anyway, even if you find paint that LOOKS similar to Harrit chips, you have to ignite them to see if they are energetic. THIS IS WHAT HARRIT ET AL DID BECAUSE THE NANOTHERMITE DESIGNERS THEMSELVES DO THE SAME DSC TEST TO SEE IF THEY ARE ENERGETIC:

Gash et al 2004 (reference nr 21 in Harrit et al paper): To determine whether the material was energetic differential scanning calorimetry (DSC)was performed.

3. You have claimed that the DSC tests are meaningless, and the kids at JREF may believe you, but as is obvious from the above quote from Gash et al, anyone who has actually done the research will know better. You have debunked yourself with this kind of BS, and it is pathetic to say the least.

You are committing FRAUD if you do not stop lying about the dsc tests. It has already been said to you that it is hard to take you seriously.

4. 'Where did you get some data that any of the Bentham chips was explosive?'

Assuming you have read and UNDERSTOOD bulletins nr 2 and 3 above, you can continue reading research by Gash et al and see how they use the DSC tests to compare the width of the peaks to determine the EXPLOSIVE POWER. They show that the nanothermite peaks are MUCH NARROWER than conventional thermite. Same amount of energy density but released in a FRACTION of the time.

So you ask 'how do Harrit et al know that the chips are explosive', and the answer is: THE SAME WAY GASH ET AL KNOW THAT NANOTHERMITE IS EXPLOSIVE.

5. Given that you are CAPABLE of understanding all this, which I doubt, and still want to continue your Paint-Gospel, you may want to realize that the with of a thermite peak is many times over broader than a nanothermite peak...

and paint provides an ever wider peak.

- Farrer et al have already tested paint in a dsc, and the results are easy to understand

http://world911truth.org/interview-with-jeff-farrer-nanothermite-paper-scientist/

Paint does not provide a narrow explosive peak at all, and neither does it produce molten iron spheres.

IT IS AMAZING THAT NONE OF YOU JREF ´DEBUNKERS´HAVE MANAGED TO SHOW THAT YOUR PRIMER PAINT MATHCES THE DSC PEAKS AND PRODUCES MOLTEN IRON SPHERES...AFTER ALL YOU KIDS HAVE ONLY HAD 3 YEARS TO DO IT.

This comment has been removed by a blog administrator.

ReplyDeletehttp://the911forum.freeforums.org/post19857.html#p19857

ReplyDeletePlease enlighten us, waiting for answers...

Excuse me, I had not checked comments here or the911forum in a while. I don't have time today and tomorrow to read and reply there, but will do so later this weel.

DeleteAre you "Ziggi"? I am ok with anonymous comments, but of course prefer some sort of identification.

There better be more primer-paint possibilities because the chips from Harrit et al are clearly not laclede, for 2 simple reasons:

ReplyDelete1) None of main ingredients,al/fe/oxygen/si/C, match the primer, some are off by a huge margin, such as fe, as has been pointed out to you.

2) the more detailed XEDS graph of sample a should show strong signals for sr and cr, the peak heights for which should be about 1/5 to 1/6 of the al and s peaks. But the tiny 'peaks' in that graph are more like 1/500 to 1/600...there is hardly evidence of clear signals for sr and cr, and more importantly not at all in the required amounts.

- Judging by their recent silence, it seems that your buddies at JREF have discovered the same thing. Points 1 and 2 above do not suggest that the chips must be your primer paint, applying Occam´s razor. Also, no-one has pointed out a primer paint yet that survives paint solvents, produces molten spheres and outperforms TNT either...not helping out from the Occam-perspective. But yet there are still people that insist that it is not only possible that they are paint, but also the most likely scenario. This is starting to look really silly.

Maybe its time to get real? REALLY.

Bye the way, you really should acknowledge the existence of organic nanothermites and hybrids..as were pointed out from the very beginning as references in Harrit et al. Think about the reason WHY they included them.

You should also know that the very same references give you examples of nanothermite with al fuel coated with...kaolin clay-like material to prevent oxidation of the al fuel. This would look like kaolin plates but in fact be especially coated al, to get the most elemental al possible.

Hi,

Deletethis is a weird comment. It appears like you haven't read the article you are commenting, or perhaps you can't see the graphs I posted?

To reply to the points you raise:

1.) Compare the first to spectra in my post above: The first is what the LaClede paint would look like, the second shows Harrit's four chips (a)-(d). Compare them: You will find that both graphs resemble each other very closely, specifically the Fe-peaks reklative to the Al- and Si- peaks are precisely what is expected from LaClede paint.

Could you please tell me out where allegedly it has been pointed out by me that ingredients are off by huge margins, and by whom? Thanks.

2.) No, you are wrong about the expected peak heights for Sr and Cr. See my first graph, it contains all the Sr- and Cr-peaks you can expect from Laclede paint: Sr would be all but invisible to the eye, and Cr shows as a very small hump around 5.4 keV whise height is more like 1/8th-1/9th that of the Si-peaks - you actually see humps in Harrit's data that are between 1/16th and 1/10th of the Si-peaks. Yep, that's less than expected, but in the ballpark; the difference can easily come from the unknown geometry and size of the samples and the EDS device, from the precise properties of the matrix, etc. For example: For my simulation, I modelled the LaClede paint as spheres with a diameter of 25 micrometers. That choice is somewhat arbitrary. If I model it as bulk material, then suddenly the expected Cr-signal has only 1/16th the peak height of Si, and then there would be "too MUCH" Cr signal in Harrit's data. The truth may well be somewhere in the middle. Conclusion still: The simulation and Harrit's data (a)-(d) are an amazingly good match for ALL ingredient elements of LaClede paint.

Where and how can you see that the Si-signal is 500-600 times as high as the Si-peak?? The Cr-peak is about 41 pixels in Harrit's detailed graph, and he caps the peaks at 324 pixels - so you can know that Si is at least 8 times as high. No more can be inferred. In fact, if the Cr-peak were 1/500th of the Si peak, it would be 1 pixel! See how wrong you are? Amazing how you can't see that!

Some more points:

DeleteI think the recent "silence" at the JREF comes from the fact that everybody has long since understood that I am right and Harrit is wrong and there's really little more to be said about that.

"No-one has pointed out a primer paint yet that survives paint solvents" - so what?

"(No-one has pointed out a primer paint yet that) produces molten spheres" - I understand this being looked into by Dr Millette at this time

"(No-one has pointed out a primer paint yet that) outperforms TNT" - WRONG. I have pointed out often that nearly EVERY organics-based primer paint can be expected to outperform TNT in terms of energy. Your earwax and your dried ejaculate also outperform TNT in that department, did you know that? It is entirely unremarkable for organics-based stuffs to outperform TNT! Why can't truther understand this simple point that TNT and thermite do NOT contain a remarkable amount of energy at all?

"Bye the way, you really should acknowledge the existence of organic nanothermites and hybrids" - why? I acknowledge that, and I acknowledge the existence of earwax and dried ejaculate. What has that got to do with the case at hand? Nothing! You are begging the question!

"Think about the reason WHY they included them" - to sell lies to gullible truthers.

"You should also know that the very same references give you examples of nanothermite with al fuel coated with...kaolin clay-like material to prevent oxidation of the al fuel." - Can you be more specific, please?

"This would look like kaolin plates but in fact be especially coated al, to get the most elemental al possible." No - a sphere maximises volume / minimizes inert (coated) surface. You are very obviously wrong.

Now what's your source that anyone has created plate-like Al-nanoparticles and coated them with anything? Please be specific (citation)!

"Think about the reason WHY they included them" - to sell lies to gullible truthers.

ReplyDeleteAre you retarded? Harrit et al point to research by the nanothermnite pioneers that includes organic nanothermites....

fx reference nr 21:

Organic sol-gel nanocomposites

In these types of composites we utilize organic sol-gel methods to produce a skeletal

matrix of hydrocarbon fuel with oxidizer added in particulate form to fill the void spaces. This

nanostructured material is unique from the thermite type materials, as it will generate significant

amounts of gas upon decomposition. In this particular example, a solid skeleton of fuel based on

resorcinol-formaldehyde has nanocrystalline ammonium perchlorate, the oxidizer, trapped within

the pores. At optimum stoichiometry it has approximately the energy density of HMX.[9] Using

a sol-gel procedure first described by Pekala to make aerogels, a porous organic solid matrix was

prepared by the polycondensation of resorcinol with formaldehyde (RF).[14] Subsequent

crystallization of an oxidizer, ammonium perchlorate (AP), within the pores of the gel matrix,

completes the synthesis, followed by atmospheric drying of the wet composite to form a dense

xerogel material.

What's described there, a "nanostructured energetic material consist(ing) of a nanostructured hydrocarbon resin fuel network with fine ammonium perchlorate (NH4ClO4) oxidizer present" (from the abstract of [21]*), is NOT thermite! It is "unique from the thermite type materials" - this is NOT thermite, and also this is NOT what Harrit e.al. found and described! It does NOT contain a metal nor a metal oxide! This organic material you reference there and the ironoxide-aluminium nanothermite they also prepared are "two totally different compositions" (again, quoting from the abstract)!

DeleteHow does this reference apply??

* Citation in ATM is no longer correct. Is now:

MRS Online Proceedings Library

Volume 800 Jan 2003, AA2.2

Nanostructured Energetic Materials with Sol-gel Methods

Alexander E. Gash, Joe H. Satcher, Randall L. Simpson and Brady J. Clapsaddle

doi: 10.1557/PROC-800-AA2.2 (About doi), Published online by Cambridge University Press 01 Feb 2011

Access via: https://journals.cambridge.org/action/displayIssue?jid=OPL&volumeId=800&iid=8005574

This comment has been removed by a blog administrator.

ReplyDeleteThere was literally tons of evidence of controlled demolitions, before the 2009 Harrit paper, such as numerous reports of molten metal, and a yellow-orange melt pouring from WTC2. For example, Leslie Robertson admitted to seeing a "little river of steel, flowing". And there is overwhelming evidence of a false-flag, e.g. Israelis caught celebrating as they filmed the attacks, and then after being arrested, lying about how they came to be seen within a few minutes of the first plane impact at a vantage point that provided a great view of aircraft approaching from both the north and the south.

ReplyDeleteSo I would like to be able to conclude "the evidence for Millette falsifying his data is compelling", presumably with the aid of "fraudulent" accomplices Oystein and Ivan Kminek. Indeed, elsewhere, a poster claims "JREF/Oystein are finished"...

But the fact is that your work, Oystein, is not only very interesting; it's of very high quality and is quite a good match to the data. And there is no evidence of fraud by Dr. Millette.

I downloaded the DTSA-II software package and ran the Monte Carlo simulations of XEDS spectra, and I can confirm that when I inputted the Oystein assumptions for "the elemental composition of LaClede Standard Primer", I replicated the spectrum as shown above. (I do have some queries about these assumptions.)

Harrit et al measured the electrical resistivity of their "thermitic" material and found it to be approximately 10 ohm-m, at least nine orders of magnitude smaller than tabulated values for "typical" paints which they found were over 10^10 ohm-m. But this is interesting: 10 ohm-m is the very value for kaolin clay, and bang in the middle of clays and fresh water. I would suggest that Millette measures the resistivity of his chips.

Harrit et al found that the "paint solvent" methyl ethyl ketone (MEK) failed to dissolve any of the red layer of their chips even after 55 hours of soaking with frequent agitation. In comparison, [normal] "paint chips" partly dissolved when subjected to the same treatment. But the fact is, a cured (crosslinked) epoxy resin does not dissolve at all in MEK or paint solvents / strippers; it merely softens.

The Laclede primer included cured epoxy resin and kaolin! Although if we suppose Harrit's MEK-soaked chip was Tnemec primer, does that also fail to dissolve? The "vehicle" is soya alkyd resin solids (16.5%), hard resin (2.8%), raw linseed oil (35.1%), thinners (32.3%), etc. Harrit's (Tnemec) swelled; Millette's (Laclede) softened as expected.

The heat of combustion of epoxy is 25 kJ/g according to Quintiere, Fundamentals of Fire Phenomena, Appendix, Table 9. Thus, if aging, cured epoxy has lost some of that due to additional oxidation, there would still appear to be enough to account for the up to 7.5 kJ/g observed by Harrit et al. There remains the fact that the exotherm for epoxy peaks below 400 C, whereas Harrit's chips exhibited narrow exotherms above 400 C. I see Ivan believes the increase in peak temperature is due to additional oxidation; it would be nice if some reference were available.

Then when we consider the gray layers, it has to be mill scale formed as Laclede rolled the shapes for the trusses. Structural steel has an ultimate strength of at least 400 MPa, compared to only 12 to 30 MPa for epoxy adhesive, which is claimed to achieve a lap shear strength to aluminum of 2,300 psi or 15.8 MPa. However, mill scale's adhesion strength ranges from 1 to 18 MPa. Thus, slivers of this could fracture away whilst epoxy remained attached. Moreover, mill scale is mostly magnetite, which is consistent with the red-gray chips being attracted by a magnet and with the gray layer appearing gray rather than the "red-brown-orange" of rust. And mill scale has a total layer thickness of around 50 microns. (Cont.)

Hello Poseidon,

Deletethanks for the in-depth critique of our work - excellent! It is excellent, because you caught some weak spots that I am already aware of:

- The uncertain composition of the LaClede epoxy with its uncertain amount of N and other elements

- The lack of N in the spectra

- My choice of assumptions for the XEDS simulations

I am at this point fully ready to admit that something is wrong about the identification of some red-gray chips specifically as LaClede paint. But our interpretation is damned close, isn't it?

As for the problem of identifying the organic matrix as epoxy in the absence of an N-signal, I´'d like to point out that Dr Millette identifies epoxy in several chips by FTIR analysis, but in all of his XEDS graphs never shows any trace of N (with the sole exception of Phase 6 in Appx G, which is primarily Al, Si, Fe, not epoxy). N is a very common element, and it is almost unconceivable that it is never even present as a contaminant, so I suspect that its absence is more a function of measuring equipment than of real absence. The Almond wrote at my JREF thread:

"The mass absorption coefficient for nitrogen X-rays in a carbon rich matrix is about 25,000 cm2/g. Any N X-rays are going to be absorbed very strongly by the matrix. Further, at 15 keV accelerating voltage, the ionization potential of N K-shell electrons is basically 0. It is entirely expected not to see see N peaks in this material."

Also, we have not found any nitrogen peaks in published XEDS spectra of epoxies and other polymers containing some percents of nitrogen.

I'd like to hear your "queries about these assumptions" concerning the input to the XEDS simulation!

Finally: I pretty much disagree with your opener "There was literally tons of evidence of controlled demolitions". How is "molten steel" (even if true, which I doubt) indative of CD? Why would anybody MELT steel in the course of a demoltion? It's overkill! And why would there still be molten steel days and weels later? No one has wrought this into a plausible scenario for CD.

Same goes for microsphere. I don't have full explanations at this point for all claims of iron-rich spheres here and there, but the conclusion that THEREFORE they are evidence of CD is labored and premature. It is basically a result of wishful thinking.

It seems that the values for N and Cl in the cured epoxy can be sufficiently low such that neither of those peaks show up. For example, there's a set of spectra on this page in which you can see a Cl peak in the epoxy resin, a very small N peak in the hardener, and then these are not visible in the mixed and cured epoxy. However, the latter includes a lot of calcium and magnesium.

Deletehttp://www.boston.com/multimedia/news/2007/big_dig/ntsb_epoxy.pdf

The perps wouldn't need to melt steel, but usage of a thermite variant would have inevitably produced some molten iron, and it would have been hard to avoid some excessive temperatures in steel members. There were numerous reports of molten steel and molten metal found in the WTC debris pile. Dr. Abolhassan Astaneh-Asl, a professor of structural engineering at Berkeley, saw widespread evidence of extremely high temperatures at the WTC. He saw melting of steel girders, fireproofing that had "melted into a glassy residue", and a wide-flange steel beam from WTC7 with parts of it that had been five-eighths of an inch-thick and had "vaporized" in "searing temperatures". According to Dr. Astaneh-Asl, the beam from WTC7 had burned prior to the building's collapse, and then buckled whilst it was still attached to a column. Leslie Robertson reported seeing a "little river of steel, flowing". Bronx fire-fighter Joe "Toolie" O'Toole saw a crane lift a deeply buried steel beam that was "dripping from the molten steel" as late as February, 2002.

WDS analysis of previously molten metal from the WTC found it to be abundant in iron whilst scarce in aluminum. (The analysis was conducted by Farrer / Jones, but surely they could not get that wrong!) Note that the molten metal was frequently seen to be dripping from steel beams. Suppose you are at a zoo or in the woods and you see a bear. Upon further scrutiny, you observe a brown material emanating from the bear's rear. Do you conclude: a) It was fecal matter excreted by the animal. b) It was chocolate. c) It is unfair to rule out chocolate, since no chemical analysis was performed on the substance.

The undebunkable iron-rich melt pouring from WTC2 (aluminum has too low emissivity and would have flowed away from the heat source long before approaching the ~1,000 C indicated by the yellow-orange color) is consistent with use of thermate (thermite plus sulfur) and an iron-sulfur melt giving up its latent heat of fusion at around its eutectic of just under 1,000 C, and consistent with the heavily sulfidated steel of "Swiss cheese" appearance that was found from WTC7. R. J. Lee found that vesicular alumino-silicate particles also had a "Swiss cheese" appearance, which was as a result of boiling and evaporation.

The iron microspheres are a mixture of those produced by controlled demolition and those produced by other means. The former are iron rich, e.g., Figure 4 in Jones' High Temperatures paper that has 18% oxygen and 65% iron. The latter are oxygen rich, e.g., their Figure 3 which had an atomic percentage for oxygen of 60 and iron of 39 indicating Fe2O3.

This comment has been removed by a blog administrator.

DeleteThis comment has been removed by a blog administrator.

DeleteThis comment has been removed by a blog administrator.

DeleteThis comment has been removed by a blog administrator.

DeleteIn another "coincidence", the police chief who announced that a "hijacker's passport" had been "discovered" was subsequently convicted of lying, conspiracy and fraud. Bernard Kerik had made a trip to Israel from August 26 - 29, 2001, that was ostensibly about fighting terrorism and Ecstasy trafficking. Bizarrely, he took no counter-terrorism or narcotics experts with him. During the trip he met Israeli billionaire Eitan Wertheimer, who was reading Popular Mechanics at the age of four. Kerik was later found to have received a so-called "loan" of $250,000 that originated from Wertheimer, and also had more than $236,000 in rent paid by Steven C. Witkoff. The mysterious stranger who supposedly "discovered" the passport was never seen nor heard of again. Of various locations cited where the passport was supposedly "discovered", all of them required a suspension of the laws of aerodynamics. The passport was supposedly "soaked" in jet fuel, yet the jet fuel was seen to ignite in a fireball. It's the fact that the jet fuel gets atomized into a fine mist, which would preclude "soaking" of objects, that allows it to ignite in a fireball at temperatures of around 10 C. If the passport maintained its original velocity as it was improbably thrown clear, and decelerated more slowly than it should have given its drag coefficient and mean cross-section (in order that it could have been found "several blocks" from the WTC crash site), then it would have outrun the jet fuel droplets. And how odd that multiple burning pieces of debris smashed their way into WTC7 to ignite multiple fires on multiple floors, and yet a passport that was "soaked" in jet fuel is supposed to have been found almost in pristine condition! The idiotic scriptwriters who came up with the "passport" story, who even claimed at one point that it had been found in the vicinity of Vesey Street to the north because they forgot that Suqami was supposed to have been on Flight 11 which approached from the north, probably just imagined that the "soaked in jet fuel" claim would sound good, and would be a way of reiterating the devastation and havoc that was supposedly wreaked by the jet fuel.

DeleteThen there is the fact that preposterous nonsense such as "hologram planes at the WTC" is propagated by intelligence assets, who typically claim to be 'ex'-MI5, 'ex'-CIA, or 'ex'-Bush Admin. If 9/11 was not an inside job, there would be no need for such attempts to discredit truth seekers.

Within hours of the attacks, Jerome Hauer went on TV to tell everyone that "It... certainly has the fingerprints of somebody like bin Laden", and that the World Trade Center collapsed because of "the velocity of the plane" and "intense heat probably weakened the structure as well". Hauer then advised White House staff to start taking Cipro, an effective antibiotic against anthrax, a week before the start of the anthrax attacks. Within days of 9/11/01, Don Radlauer, of the Interdisciplinary Center at Herzliya, Israel, published a report suggesting that hijacking and steering the planes would have been an easy task - even though the rather diminutive non-pilot Hani Hanjour was said to have wrestled control of Flight 77 from the tough, highly trained, weightlifting former Navy fighter pilot Charles Burlingame and steered a Boeing 757 to smash into the Pentagon's first floor at 530 mph as its engines cleared the lawn by a couple of feet - or less than that for one engine after allowing for the roll. In April 2004, Eddie Guigui Shalev, an Israeli national who served in the Israeli Defense Forces in the paratroops regiment, said that based on his observations, Hani Hanjour was a "good" pilot. This of course was contrary to all available evidence. We could go on and on. I hope you can see that there is more than just a little wrong with the official conspiracy theory...

This comment has been removed by a blog administrator.

DeletePoseidon,

Deletethanks again for your replies - well, for the first part of your first of five replies anyway.

I deleted the content of the four others, and Ivan's reply to them, because they went massively off-topic to this blog post, and also ran counter to the way I originally wanted to handle this blog, however I copied and pasted all five deleted posts into a txt-file which you find here:

http://dl.dropbox.com/u/48905765/20120507_deletedComments_PoseidonIvan.txt

Please do not spam my blog in the future, or respond to spam. Thanks.

--------------------

Now on to the paper with analysis of actual epoxy:

http://www.boston.com/multimedia/news/2007/big_dig/ntsb_epoxy.pdf

Very nice, thanks! As for your observations:

"It seems that the values for N and Cl in the cured epoxy can be sufficiently low such that neither of those peaks show up. For example, there's a set of spectra on this page in which you can see a Cl peak in the epoxy resin, a very small N peak in the hardener, and then these are not visible in the mixed and cured epoxy."

It is my understanding that some epoxide resins may contain Cl, but others do not. I find no particular reason to believe that the LaClede primer used an epoxide with Cl, though it's possible. So absence of Cl is no problem. In fact, the "Fast Set" epoxy resin in that paper shows no Cl, only the "Standard Set" resin does. So there's more proof that Cl is "optional".

However all epoxies, pretty much by definition, have hardeners with amine groups (contain N); in fact the LaClede primer spec is explicit about the "epoxy amine". There is every reason to assume that the adhesive epoxy that your paper reference looks at contains a "normal" amount of N, and so it is indeed a relief for us to see that the cured "known" epoxies (fig. 3, 6) show no discernible signal for N!

"However, the latter includes a lot of calcium and magnesium.

Yes, because these epoxy formulations contain slightly more than 30% mineral fillers, with calcium carbonate and magnesium silicate specifically mentioned in the Material Safety Data Sheets for both Sets - probably to control viscosity and similar physical properties. These are not components of epoxy proper. The role these mineraly play in the adhesive analysed there is filled by the aluminium silicate in the LaClede paint, where I assume that the 71.5% epoxies are specified pure, sans further fillers.

Oystein,

DeleteIt looks to me like the "Fast Set" has a small Cl peak. But they haven't labelled it, and it's more ambiguous than the "Standard Set". Anyway, I am satisfied that the questions about Cl and N have been resolved. The peaks don't show up in the cured epoxy.

Here's something that I can't quite explain: Harrit / Farrer's DSC traces have one main peak, but the thermogravimetric analysis curves for epoxy shown in Herbert W. Moeller, Progress in Polymer Degradation and Stability Research have a secondary peak at around 550 C.

http://books.google.co.uk/books?id=Xh2x1-5OVeYC&lpg=PA224&ots=h-FxbEBS91&dq=%22derivative%20thermogravimetric%20curves%20in%20atmosphere%20of%20air%22&pg=PA224#v=onepage&q=%22derivative%20thermogravimetric%20curves%20in%20atmosphere%20of%20air%22&f=false

In Chapter 8, Macan and Ivankovic's Figure 11, which is for an oxidative atmosphere, there is a secondary peak at around 550 C. (Their Figure 4 is for a nitrogen atmosphere, and only has the main peak at approaching 400 C.) So their test in air has further mass loss occurring at the higher temperature. They say it's combustion of char that remained after the first degradation step. So it should be exothermic. I think you pointed out that Harrit / Farrer's four DSC traces are all different, and have some other small peaks. But somehow, Farrer didn't have any exothermic reactions at 550 C and up from char combustion.

There is also a Chinese paper with similar results to Macan / Ivankovic; their Figures 9 and 10 show TGA plots for oxidative atmosphere of air.

http://wenku.baidu.com/view/da4911659b6648d7c1c7469f.html?from=related

It's your blog so it's up to you how you want to handle it, but I believe any investigation of 9/11 is seriously incomplete without looking into the evidence of who did it. Much of the information has been known for years, and may be seen for example in Dr Albert Pastore's Stranger Than Fiction. I posted a sixth comment that initially appeared, but it later mysteriously vanished. You "debunkers" ignore evidence that you don't like, whereas I am prepared to give any evidence a fair hearing even if it doesn't support my conclusion. Still, you have done useful analysis of the Harrit paper, have presented it excellently, and there are things we agree on.

Hi, Poseidon, thanks for this post.

DeletePls try to stay on topic like in this your contribution, thanks in advance:o) This debate should be on red-gray chips in WTC dust and nothing else belongs here.

You are right: when epoxide resins are heated under air, they usually show two stages of oxidative degradation; the second stage, a (minor) loss of mass is usually observed around the temperatures ca 550 degrees, and it corresponds to the burning of "char" (dark polyaromatic/graphitized mass), as is recorded by TGA.

But do not take this behavior as a rule, since epoxy burning could be influenced by many factors, like exact chemical composition of epoxy, degree of cross-linking, the amount, chemical nature and particle size of pigments/fillers, even the age of the sample etc. Even in the Macan and Ivankovic's article you cited (I consider this article as very important, since it shows some DSC curves) you can clearly see a quite different thermal behavior for various epoxy samples.

Try also bear in mind:

1) We simply do not know if all/any sample burned in DSC device by Farrer contained epoxy/were particles of Laclede paint. Some of samples can be

particles of Tnemec paint (with cross-linked alkyd-linseed binder) or any other red paint.

2) TGA curves (which are usually recorded in polymer degradation papers) do not fully correspond to DSC curves (if any such curves are measured).

3) We are definitely not sure that any DSC curve in Bentham paper belongs to Laclede primer. But we are pretty sure that none of these curves can be regarded as a proof of thermitic reaction. They are two apparent reasons: a) the exothermic reactions observed are very slow (taking place during 5 to 10 minutes); b) Released heat exceeds the theoretical heat which can be released by thermitic reaction.

Hi Poseidon,

Delete1.) On elemental composition: Yes, we have agreenent. I'd like to point out again that, while N always is a constituent of cured epoxy, Cl can be, but isn't always. We don't know whether any Cl was contained in LaCledes formulation.

2.) On DSC charts: Thanks for again finding these instructive sources!

As Ivan has said already: We don't know which type of chips Farrer tested when he plotted the 4 graphs in Figure 19 of ATM. I have speculated elsewhere that he had 2 different types: the green and black being one type, red and blue line the other, but could as well be 3 or 4 different types. The red line alone has a distinct second peak, at about 455°C (first peak: ca. 435°C).

Why there is not a second peak I can't tell, but that is not only a possible problem for an epoxy-theory, but more so for the thermite theory: You would very much expect at least two peaks - one (or more) for the organic matrix, another for the thermite proper. The fact that 3 of 4 chips in Farrer's have only 1 peak despite very likely being organic in nature strongly speaks for them not containing thermite.

And also, as Ivan points out: The very fact that 3 of the 4 curves reveal an energy density that is too high for thermite, is proof positive that the main peak is caused by something that is not thermite.

So Farrer's DSC test, while being inconclusive about what these chips are, is conclusive on that they are NOT thermite (or at least that no thermite reaction takes place).

3.) On everything else and how I handle my blog:

It's mainly a matter of practicability. This is a blog and not a forum, and also not a wiki. Ths format does not allow for complex, branched out, multi-topic debates.

PLUS: When I set it up under this name: "Oystein's 9/11 debates", I had in mind debating single issues in depth. See what I write just under the header:

"What is your one (1) single most convincing argument? Your strongest evidence? Your most damning fact? State it as precisely as you can, and convince me!"

The idea behind that being: If what you think is your best argument turns out to either be not true or not actually argue against the "official story" or in favor an alternative one, then chances are none of your arguments are good. I don't mean to say that your best single argument alone makes or breals the case, but it should at least change significantly the odds for one story being true and another being false. Once I accept that your best argument is good, we can try the second best.

I predict that no one will meet that challenge, but of course I can be surprised.

If you think you are up to that challenge, say so here, and I will think about how we can start it. Perhaps give me your email address, or I'll post mine.

4.) On disappearing comments: The Anonymous poster, who surfaced at the911forum as Ziggi where he was quickly banned a day before I could engage him, also said that comments he wrote had disappeared and naturally accused me of censoring him, but I really have no idea what happened then, or what happened with your 6th comment :-/

Ivan, Oystein,

DeleteOkay, then, it's fair to say that because there are plenty of unknown variables, and because in any case DSC does not fully correspond to TGA, and we don't even know which chips were used in Farrer's DSC tests, we cannot say that because some epoxy DSC charts don't quite match Farrer's tests, then Farrer has refuted the paint chips thesis.

I'd been wondering if there had been some thermitic reaction from unreacted thermite that had got mixed in with paint chips. This seems contrived, because the iron oxide already existed in both the Laclede and Tnemec primer. Aluminum originating from curtain wall panels might explain the elemental aluminum found in the Harrit MEK soaked chip. If Harrit's Figure (7) samples (a) to (d) are Laclede primer, and the Figure (14) MEK soak chip is Tnemec primer, the Tnemec perimeter columns might have been more likely to have some elemental Al contamination from curtain wall panels. Small pieces of this elemental Al would probably be micro-sized rather than nano-sized, so you would not expect to see any thermitic reactions ignited by temperatures of up to 700 C. If Laclede primer paint chips were more prevalent than Tnemec paint chips, then most chips, and those tested by Millette, could have the aluminum bound with silicon and oxygen. Those with elemental aluminum contamination would be the exception rather than the rule.

And then we still don't know which chips were used in the Farrer DSC tests, and there is even the possibility of a third or fourth primer! In conclusion, the paint chips hypothesis is the best fit to the data.

Oystein,

I agree your blog format is better for debating some special topic in depth; you wouldn't want people discussing reptilians, or "nukes" in the WTC basement that were successfully covered up by the Nixon admin. But the person who has to defend some particular piece of evidence is at a disadvantage. Typically, some superficial refutation would be devised. And if the pro-government side had to present their strongest evidence, that could be amusing: they might cite the claim that a passport was "discovered" in pristine condition after being "soaked" in jet fuel, or a red bandana was "found" in perfect shop display condition when the aircraft, seats and just about everything else was pulverized into tiny pieces of scrap, or that some guy "confessed" to being responsible for the "9/11 Operation, from A to Z", the "1993 World Trade Center Operation", the "Shoe Bomber Operation", the "bombing of a nightclub in Bali", etc, after being waterboarded 183 times...

Another point is that there are many, many pieces of evidence against the official 9/11 theory. Each side having to defend their best evidence would be fairer than one side defending, although it could still hand some advantage to the pro-government side, since the truth advocate would only be presenting a much smaller proportion of the pro-truth evidence. (When I compiled just a fraction of such evidence and split it up into six comments to post here, the sixth comment was still too large originally, and so I had to cut out some material rather than extend to a seventh comment!) However, I wouldn't want to get into such a debate at this stage as they are too time-consuming; I'll continue to research and follow events with a great deal of interest. If active thermitic material really had been found, the debate would be over. Now, we can be sure that it will run on.

Poseidon, as for alleged aluminium found in the MEK chip, I would disagree. I don't see any real proof of this metal (in elemental form) in that chip. Allow me one repost of my older contribution from JREF:

Delete"Please try to accept the apparent fact that MEK chip was another material than chips (a) to (d) and let us consider this chip to be a particle of Tnemec paint.

According to specification, as for Al and Si stuffs, this paint contained 1) "diatomaceous silica", 2) "crystalline silica", 3) "talc", 4) "calcium silicates and aluminates" and 5) "amorphous silica".

These components/pigments have formulas (variable in some cases) :

1) (Mostly silica) SiO2

2) SiO2

3) H2Mg3(SiO3)4

4) Ca2Si04, xCaO·Al2O3

5) SiO2"

Shortly, there were particles of al least 6 different pigments in this paint. No wonder that those particles were separated during soaking of Tnemec paint chip, leading to some separation of Si and Al rich areas. This is exactly what can be expected during this process in the case of this paint. Since chip substantially increased its volume owing to polymer binder swelling in MEK solvent, various pigment particles migrated and Si and Al rich particles became better separated/differently distributed in the binder, which was shown in corresponding XEDS maps.

(But such process cannot proceed in the case of Laclede primer, which contained only one Si-Al pigment (kaolinite). Note that there is no such separation in Fig. 10 in Bentham paper, Al and Si-rich areas in XEDS maps coincide perfectly)..."

Ivan, your explanation could account for how Al and Si separated during the MEK soaking of the Tnemec pain chip. But Harrit Figure (15) shows that there are Al-rich areas with little accompanying O, and this is confirmed by Figure (17). The soaking could not reduce the Al2O3 compound, since reduction of Al2O3 is an endothermic reaction that will not proceed without an energy source (which exceeds that released from oxidation of Fe for example). So I suggest Al contamination from curtain wall panels.

DeleteOK, Poseidon, you can be right and Fig. 17 in Bentham paper could show us just some accidentally present aluminium particle (slightly oxidized), since the oxygen peak is quite low in comparison with Al peak.

DeleteStill, I would be very careful in this respect, since the ratios between peaks are quite variable in XEDS spectra for numerous reasons and Harrit et al probably chose just one spectrum which somehow proved their thermite hypothesis. By no means this one single XEDS spectrum can be regarded as some proof of by far the worst/most horrible crime in the history of mankind:o) Harrit et al had definitely to present more XEDS spectra of Al-rich areas, to be at least slightly convincing.

As concerns Fig. 15, I see some areas where Al and O are detected on the same place (mostly on the right side of the chip) and other areas where Al seem to be "separated" (mostly on the very left edge of the chip). For me, this is not convincing as well. (But I have to admit that I am a polymer chemist and all these things like XEDS elemental maps are not exactly my job ot pot of tea:o)

BTw, I would like to know, which Al-rich area (poor in oxygen, according to XEDS maps) is recorded on Fig. 17. This is quite normal, to show recorded area, as I know e.g. from Jim Millette's paper.

DeleteNote again that the areas especially rich in Al basically coincide with the very left edge of the chip, where the chip surface is not perpendicular with the bombarding electron beam (as we can easily judge from the Fig. 17a). Perhaps XEDS signals (e.g. ratio between Al and O peak) can be somehow influenced by this geometry. But, this is just my unsupported speculation:o)

Just one correction of previous post for clarity: "as we can easily judge from the Fig. 15a"

Delete@ Poseidon,

Deletea late reply, sorry:

1. I don't think that any elemental aluminium from the perimeter cladding would make its way into or onto chips of primer paint, even if both started their journey during collapse in close proximity. I believe even less that such a grain of Al would have reacted with the iron oxide pigments. All that is not physically impossible, but rather far-fetched. I find Ivan's observation and speculation that the geometry of the chip influences the XEDS measurements such that the region where Jones claims to have found with at least some elemental Al does not do so in fact. We are currently discussing this at the JREF with someone who has lots of hands-on experience with SEM-XEDS, and indeed it appears that relative peak heights can only be interpreted quantitatively with some confidence if the sample surface is sufficiently flat and perpendicular to the line of sight of the detector - both conditions that do not apply at all here. In addition, I suspect, but haste to point out that I am a layman and my suspicion is not to be taken as authoritative, that the strong Al-signals in Figure 15, as well as some of the C -signal there right at the edge of the chip, originate not from the ship, but from the sample holder, which most likely was "an aluminum pedestal, using a carbon conductive tab" to hold the chip (quoted from the caption to Figure 2). If this is at least parially true, then we can't have any faith in Fig. 17, the XEDS chart that shows lots of Al and little O and other stuff.

2. I understand how you are unhappy with the debate format I outlined, and yes, it would appear fair to play that game both ways. However, your example, the Al Suqawi passport found near Vesey street, would not be close to being my "best evidence" for the official story. It is a curious piece of corroborative evidence, but by itself doesn't tell a lot. I'd probably look more at ATC transcripts, or the way the flight 77 FDR corresponds to radar data, the colmplete body of eyewitness testimony, ATC transcripts, and analysis of damage on the ground.

However, the official story has several aspects, which might require several distinct lines of "best evidence". I'd ask you first which aspects you disagree with, and which you do agree with or have no opinion on. If you agree that terrorists flew planes into four buildings, there's be no need for me to prove that.

There is an imbalance here between "truthers" like you and "debunkers" like me: You have a pretty good idea which theory, or story, I subscribe to; it is layed out in official documentation in great detail and completeness, and most of it is also unambiguous and agreed upon by most on "my" side. On "your" side, the picture is vastly different: Precious few, if any "truthers", have a complete and detailed alternative story, even less one that anyone else agrees with. So you need to explain to me which parts of the official story you consider to be wrong. Better yet: Tell me the alternatives in the form of a falsifiable theory.

It's not physically impossible that the elemental Al in Figure (15) (c) is some fluke of geometry and Harrit's apparatus, but I think that's rather far-fetched. The geometry wouldn't account for Al with little or no O in places other than the left of the image, such as the right-center, and top left-of-center to top-center. Moreover, the elemental Al in Figure (15) is corroborated by iron-rich spheres found in the residue after Farrer's DSC tests. Some of these spheres actually had higher Fe:O ratios - e.g. Harrit's Figure (21), than some of those obtained from igniting "commercial thermite" - e.g. Figure (24). Harrit et al estimated, by a "conventional quantitative analysis routine", that the iron content exceeded the oxygen content by about a factor of two in the Figure (21) sphere. Other spheres observed exhibited "Fe:O ratios up to approximately 4:1", which is evidence for a thermitic reaction, and is the strongest point in the arguments advanced here by Anonym.

DeleteAl contamination could explain Figure (15), but couldn't explain the formation of iron-rich spheres with an excess of Fe over O and demonstrating that elemental Fe must have been present. Particles of Al from natural contamination would have been too large to ignite a thermite reaction at 700 °C. It seems far-fetched that Farrer or Millette deliberately doctored their samples, whether by adding nano-sized elemental Al, or by substituting paint chips for unreacted nano-thermite. And it seems far-fetched that the perps would disguise their nano-thermite to look like Tnemec paint - and Laclede, unless Harrit's iron-rich spheres were only seen with Tnemec chips. However, if the fireproofing had been laced with nano-sized Al particles, along with 100 nm iron oxide particles as found in the paint, any paint chips found might have contamination with this nano-sized Al, which could show up as elemental Al in an MEK soak, and could go on to produce iron-rich spheres from a thermitic reaction ignited at 500 - 700 °C. The paint chips would still look very much like paint, and the thermitic reaction would be a tiny proportion of the exotherm. Another possible phenomenon might be vesicular alumino-silicate particles with a "Swiss cheese" appearance as a result of boiling and evaporation, but this would more likely be seen in the dust rather than replicated from a small nano-aluminum contamination of paint chips that include Fe2O3.

For "truthers", it's a bit of a shock to see that the "debunkers" were not lying about paint chips. There is a lot of evidence supporting the paint chips thesis. But that doesn't mean that Harrit et al are liars or idiots who should hang their heads in shame; they did provide evidence for a thermitic reaction that ignited at 700 °C or lower, and hence was nano-thermite. Now, they should admit the flaws in their paper, and build on what they got right.

Apart from the iron-rich spheres, another mystery is that of the single-wall carbon nanotubes discovered in the WTC dust and in the lungs of people exposed to the dust. The report said that this was "unexpected and requires further study".

For the honest truth seeker, the best way to understand 9/11 is not through debates, but by comparing the two hypotheses "Islamic terrorists masterminded 9/11" and "Zionist terrorists masterminded 9/11". Look at how many absurdities, improbabilities, impossibilities, anomalies and bizarre 'coincidences' spring up in each case. When you assume the wrong hypothesis to be true, there will be a host of these improbable 'coincidences'. When you assume the correct hypothesis to be true, the oddities and absurdities are suddenly explained as part of the causal chain, and thus are normal, natural, and totally expected. A good few of the absurdities are narrated in under five minutes in The Corbett Report's "9/11: A Conspiracy Theory" on YouTube.

Poseidon,

Delete"The geometry wouldn't account for Al with little or no O in places other than the left of the image, such as the right-center, and top left-of-center to top-center."

But how do you know there is any region with "Al with little or no O in places other than the left of the image"? We don't know where Figure 17 was measured, and know even less what would be measured elsewhere.

"Moreover, the elemental Al in Figure (15) is corroborated by iron-rich spheres found in the residue after Farrer's DSC tests. Some of these spheres actually had higher Fe:O ratios - e.g. Harrit's Figure (21), than some of those obtained from igniting "commercial thermite" - e.g. Figure (24)."

How can you corroborate any claim about Al in one particular chip with data not on Al but on Fe obtained from chips of unknown composition and properties? There are several large leaps of faith through uncharted waters involved before you can call that a corroboration.

Anyway, in Fig. 21 you have a ratio of peak heights of O:Fe(L-alpha) of about 3.67:1. The same ratio in Fig. 6 (a)-(d) are 2.67:1, 2,36:1, 2.24:1 and 2.34:1. So it would appear that this post DSC spherule has the iron actually even more oxidized than it was in the gray layers, which consist, as Harrit e.al. mention somewhere in their paper, mainly of inert iron oxide. And indeed, it makes sense: The top layer of steel usually has a gradient from fully oxidized iron (Fe2O3) through Fe3O4 to only partially oxidized FeO. (Notice that in Fig 21, the Fe K-alpha peak is 9 times higher than the Fe L-alpha peak, in Fig 6 it's only higher by a factor of about 1.5-3.25. I tend to distrust their quantification here). Anyway, when "the iron content exceeds the oxygen content by approximately a factor of two" (ATM page 21), and that is by weight, then that corresponds to a mol ratio Fe:O of 1:1.75, which is more O than needed to make Fe2O3 (1:1.5). Even a by-weight-ratio of 4:1 is only 1:0.875, perhaps close enough to 1:1 (FeO) to be explained by imprecision of quantifying XEDS peaks.

"they did provide evidence for a thermitic reaction that ignited at 700 °C or lower, and hence was nano-thermite."

No. They have iron that isn't fully oxidized, that's all. To prove a thermitic reaction took place they also need to show they had elemental Al before, which they didn't, and Al2O3 after, which they didn't, in the same speciment that they put in the DSC and gained DSC traces from. However, we have no information whatsoever about what went into the DSC to obtain these traces, and what they found analytically from these 4 experiments in the residue. Again, there are major disconnects in their study, and you are making long leaps of faith to accept their claims.

"Apart from the iron-rich spheres, another mystery is that of the single-wall carbon nanotubes discovered in the WTC dust and in the lungs of people exposed to the dust."

But not discovered in their experiments. It is a large leap of faith to assume that this has anything to do with the totally evasive nanothermite.

Please refrain from introducing unrelated topics in this current debate. We are discussing the chemical and physical analysis of certain dust particles that certain truthers consider to be suspect. Nothing more.

Oystein,

DeleteFrom ATM Figure (15) it can be seen from a comparison of XEDS maps (c) and (d) that there are a number of regions rich in Al but with little or no O, other than the more obvious zone on the left of the image.

There is much data that corroborates thermite-based deceptive demolitions, although if I present it you'll say it's off-topic. Iron-rich spheres (formed from temperatures in excess of the 1,538 °C melting point of iron or 1,565 °C for Fe2O3) and elemental Al - which has to be nano-sized to ignite at 500 to 700 °C to create those spheres - are two more corroborating pieces of evidence.

Forget the L-alpha peaks; those are all over the place and clearly unreliable. The ratio to consider is Fe:O, going by the K-alpha peaks. So in ATM Figure (21) the ratio is 2.4:1 Now if you run a simulation on DTSA-II (as mentioned above), input the values Fe 2 atom(s) and O 1 atom(s), (Monte Carlo model of a sphere on a bulk, homogeneous substrate), the Fe K-alpha peak is at just over 9 and the O peak has a value of just under 4, a ratio of just over 2.25:1 and not far out from the Figure (21). In fact, it suggests that Harrit's Figure (21) corresponds to an Fe:O ratio of a little more than 2:1. Of course, Harrit, Jones et al are talking about atomic ratios (not mass ratios). See page 19, for example, where they say that an Fe:O ratio of "approximately 2:3" corresponds to Fe2O3. An Fe:O atomic ratio of 4:1 is 13.96:1 by mass!

In Harrit's gray layer spectra, the corresponding Fe and O peaks are averaging about 1:1 (ranging from O slightly lower than Fe, to O slightly higher than Fe). So their spheres with a 4:1 Fe:O ratio have an extra three iron atoms for every iron-oxygen pair in the gray layers.

The small quantity of Al2O3 would have been dispersed as an aerosol. It's always nice if you can convict someone on multiple lines of evidence, e.g. forensic and eyewitnesses. But we don't need the Al2O3; it's enough to know that iron oxides cannot be reduced to elemental iron plus iron oxide along with consequent melting without either a chemical reaction such as a thermite reaction, or a breakdown of the laws of thermodynamics. It shouldn't happen with paint chips in a 700 °C DSC test.

A typical JREFer's specious argument is to cite the Centre for Industrial Photonics' statement that "...for example, the melting temperature of iron particles in the range of a few nanometres lies approximately between 200 ~ 400 °C compared to 1538 °C for bulk iron". Intuitively, one might imagine that there could still be a significant melting-point depression in the microns range. However, the Wiki page for melting-point depression shows that the microsphere melting point divided by bulk material melting point hits a value of 0.8 on the y-axis for a particle diameter of under 25 nm, and melting-point depression is negligible in the microns range. Moreover, Steven Jones found iron-rich spheres up to 1.5 mm in diameter!

You've helped to show that the red/gray chips were paint chips. But ultimately, the iron-rich spheres cannot be explained away without invoking a thermite reaction or magic. The thermite reaction can be explained as paint chips contaminated by active thermitic material, or merely by the ATM's nano-aluminum reacting with iron oxide in the paint. The ATM paper could have been better, but Harrit et al deserve kudos and a place in history for discovering evidence of thermite at the WTC. The "debunkers" may have won a battle, but they have lost the war.

@ Poseidon,

Delete"From ATM Figure (15) it can be seen from a comparison of XEDS maps (c) and (d) that there are a number of regions rich in Al but with little or no O, other than the more obvious zone on the left of the image."

I pointed out earlier that 15(d) shows areas that are curiously poor in oxygen, even though there should be plenty of oxygen everywhere where there is also iron. Fig 15 also shows large areas which seem to contain pretty much none of the 5 elements tested here. To me this appears very much as if the XEDS map measures less the absolute presence of atoms and more the physical shape of the surface of this clearly un-flat chip - and chances are big that this influence of geometry affects different energy levels differently. This would then also have a significant effect on every XEDS measurement taken from that rugged surface.

...

(I have been working on this post for a couple of days now, but spending little net time; mostly looking very closely at several XEDS graphs; and not quite coming to grips with what I am looking for. So perhaps a more detailed reply will follow later, just want to get this out now)

(tbc)

(ctd.)

DeleteI tell you what my suspicion is: Most XEDS and SEM work has been done by Farrer, who is good at it (he is the TEM lab manager at BYU, he does that stuff all the time), but he wasn't involved in the work on the MEK chip - that stuff ist just so all-over-the-place, inconsistent with the choice of 3 different beam energies, Fig. 14 from an unclean specimen (which still reveals enough detail to rule out it's the same as a-d, and instead very similar to Tnemec), Fig. 16-18 from unknown spots on the chip (hence with unknown geometry)... Farrer's data on the other hand (chips a-d, and probably the post-DSC specimens, Fig. 21 and 25) appears consistent and well done. Chips a-d of course are very much in line with LaClede, while Fig. 25, upon quick glance, is a plausible signature of some burned red paint (not LaClede): With a strong hematite signal, some Ti; Ca Si and Al are also very usual in many paints; and,compared to unburned paint (Fig. 7 and 14), most of the C and a good proportion of the O went simply away when the organic matrix burned (remember: Most of the mass of paint is organic vehicle, and this vehicle contains oxygen, too. In my estimate of the elemental composition of LaClede primer, O is 21% by mass and C 48%, and of the 21% O, about 9% are bound to epoxy, 12% to the minerals. If you burn most of the epoxy, the concentration of O relative to the metals that stay behind decreases by some 40%, hence it is entirely within expectation that Fig. 25, XEDS from a burned paint chip, has an O peak lower than Fe and almost on par with Si, while the unburned paint in Fig. 7 and 14 exceeded that of the most common metal by roughly 50%)

So how do I explain Fig 21 (high Fe, low O, post DSC), within my framework? I can't at this time; but I still do wonder how little the L-alpha peak of Fe is relative to K-alpha, and this ratio (1:9) compared to that in Farrer's other spectra (1:2 in Fig 11b, 1:7 in Fig 25, 1:1.5 - 1:3 in Fig 6 - it seems the two Fe-peaks are closer to each other when there is only little material other than Fe and O)

Hi Oystein,

DeleteMy interpretation of Harrit Figure (15) is that the sensitivity to O was turned down somewhat in (d), because they wanted to show how it was a good match with the Si in (e). The Si:O ratio is 2:9 for kaolin, whereas the Fe:O ratio for Fe2O3 is only 2:3. So, there are some Fe-rich regions in (b) that appear poor in oxygen in (d). Yet when they focus on an iron-rich region, Figure (18), they find that the oxygen does indeed exceed the iron, and calculate the ratio at 2:3 "after accounting for oxygen fractions to trace elements", consistent with Fe2O3. However, when they focus on an Al-rich region, Figure (17), they get little oxygen, and even less silicon. If an effect of geometry is attenuating the lighter elements, it is very odd how there is no attenuation with Al (atomic weight 26.982), considerable attenuation with O (15.999), and even greater attenuation with Si (28.085).

If the Al is from thermite contamination as I suspect and Harrit's MEK chip is Laclede paint, then I'd expect the Si phase to include plenty of Al. But Figure (16) has very little Al, suggesting the chip was another primer.

When you burn the epoxy, its oxygen would be given up as H2O and CO2. And N goes away too. But you should be left with the minerals in the paint pigment: Fe2O3 which has more O than Fe, and (assuming Laclede primer) kaolin / aluminum silicate which has an even higher O proportion. Reducing the Fe2O3 would be endothermic, so this only happens in a redox reaction such as thermite in which a more reactive metal than Fe happens to be present in elemental form.

I find in a simulation of C 4 atoms, O 1 atom, Fe 4 atoms, the ratio Fe l-alpha to k-alpha is about 1:2.1, and when increasing C to 12 atoms, the ratio goes to 1:2.42, which is consistent with your closer peaks when there is little material other than Fe and O. That was for a beam energy of 20 keV, which is why I used a lot of C. Going to 10 keV, the C shows up much more. And with only Fe at 10 keV, the Fe l-alpha peak is more than 5 times _higher_ than its k-alpha peak!

Anyway, I now think I understand what's been going on, and your work and comments have been very useful. By the way, did Jim Millette ever recover his "memory lapse" of March 13 in which he told Chris Mohr that he was "unclear" about which samples he'd washed for the MEK soak? And did he ever reply to Mohr's (originally Ivan's) question of February 3 about how he cleaned his chips?

Tests on clean chips help to identify the primer, but will not find thermite. It would be a waste of money to do DSC tests of clean chips; you'd only see burning of organic material. If you find, say, ten iron-rich spheres of 5 microns in diameter (a high estimate; the best post-DSC spheres were about that size), assuming density of 7,000 kg/m^3 a little closer to iron than iron oxide, each sphere is 6.54 x 10^-17 m^3 and the mass of ten spheres is 4.58 x 10^-12 kg. Assume about half is iron oxide and half is iron, but the Fe product is about half the mass of thermite. So 4.58 x 10^-12 kg x 3.9 MJ/kg leaves 1.8 x 10^-5 J as the yield from thermite (you were right about it not damaging apparatus!). Jones' biggest chip was 0.7 mg, so if the red layer is just 0.1 mg and its yield only 7.5 kJ/g, then the epoxy releases 0.75 J and the epoxy : thermite yield ratio is more than 40,000:1. Even if the difference is just 3 orders of magnitude, the yield from the thermite contaminant is too low to show up as a secondary peak on the DSC curve (presumably at ~520 °C in line with Tillotson).

More efficient would be to remove and isolate surface contamination on the "as collected" outer surface of the red layer, do XEDS on a clean cross-section of a red-layer to identify the primer, do an analysis of the contaminants, and then heat the contaminants to 700 °C and look for iron-rich spheres.

Poseidon,

Delete"My interpretation of Harrit Figure (15) is that the sensitivity to O was turned down somewhat in (d), because they wanted to show how it was a good match with the Si in (e)."

Perhaps. But:

"The Si:O ratio is 2:9 for kaolin"

I see no reason to believe there is kaolin in the MEK chip. See Fig. 16, which shows Si and O and nothing else, so in that chip, at least Si is silica - Si:O ratio 1:2.

"However, when they focus on an Al-rich region, Figure (17), they get little oxygen, and even less silicon. If an effect of geometry is attenuating the lighter elements, it is very odd how there is no attenuation with Al (atomic weight 26.982), considerable attenuation with O (15.999), and even greater attenuation with Si (28.085)."

I find this Al-signal highly suspicious for reasons I already stated: It is very strange that the highest density of Al, and in fact almost all of the Al, is on the outmost rim of the chip, and on surfaces that are far from being perpendicular to the "line of sight" of the xray detector. There is no reason why soaking with MEK should push all the Al to just these areas. I suspect that most of the Al-signal comes not from Al inside or on the chip, but from outside.

"If the Al is from thermite contamination as I suspect"

Which thermite contamination? Harrit e.al. have it the other way round, they think that chip is thermite, contamination is paint. But neither they nor you can actually point to any contamination. It isn't shown anywhere. You are both assuming that which you want to prove, methinks.

"and (if) Harrit's MEK chip is Laclede paint, then I'd expect the Si phase to include plenty of Al. But Figure (16) has very little Al, suggesting the chip was another primer"

I have always argued that the MEK-chip is very different from LaClede (see http://oystein-debate.blogspot.de/2012/03/why-red-gray-chips-arent-all-same.html), and in fact believe it very likely Tnemec (see http://oystein-debate.blogspot.de/2011/03/steven-jones-proves-primer-paint-not.html).

(tbc)

(ctd)

Delete"Reducing the Fe2O3 would be endothermic, so this only happens in a redox reaction"

I see no reason to assume that much or any of the Fe2O3 pigment was reduced - all of the post-DSC residues have mostly retained the characteristiv red color of it.

"such as thermite in which a more reactive metal than Fe happens to be present in elemental form."

Metals are not the only option - CO would do the same, in fact almost all steel is made by reducing iron oxides with CO.

As for simulating different C:O:Fe ratios at different beam energies: Yep, I know in rough outline how these variable have influence on relative peak hights; but the simulation can't account for unknown geometry, and only imperfectly for the different absorption properties of different matrix materials.

"By the way, did Jim Millette ever recover his "memory lapse" of March 13 in which he told Chris Mohr that he was "unclear" about which samples he'd washed for the MEK soak? And did he ever reply to Mohr's (originally Ivan's) question of February 3 about how he cleaned his chips?"

I haven't followed that up, so I don't know. You are talking about the JREF thread on Millette's study, right?

"Tests on clean chips help to identify the primer, but will not find thermite. It would be a waste of money to do DSC tests of clean chips; you'd only see burning of organic material. ... More efficient would be to remove and isolate surface contamination on the "as collected" outer surface of the red layer, do XEDS on a clean cross-section of a red-layer to identify the primer, do an analysis of the contaminants, and then heat the contaminants to 700 °C and look for iron-rich spheres."

Well interesting idea :D Again, since Harrit e.al. have left us no information at all about surface contamination (the only mention I recall of contamination is the big handwave that all the major differences between Fig. 14 and Fig 7 are declared contamination, without evidence or argument).

Silica (SiO2) is consistent with Tnemec paint and Harrit Figure (16). You showed there are some striking similarities between Figure (14) (pre-soaked "as collected" outer surface of red layer of MEK chip) and Jones' XEDS of "primer paint from actual WTC steel" (WTC2 floor 55). Yes, they mislabelled Ca as C. If the MEK chip is Tnemec, then it has not only SiO2, but also 12 - 17% (according to Harrit's calculation of composition in dry paint) talc (Mg3Si4O10(OH)2). And there are calcium silicates (Ca2SiO4). Thus, the Si:O ratio is about 1:3, and with twice as much O associated with Si as with Fe, there is a better match between Si and O rich areas in Figure 15 than between Fe and O. However, I find there are too many inconsistencies between Tnemec paint and the MEK chip after soaking.

DeleteAfter the MEK soak, there is Al with little else apart from C and O (insufficient O to oxidize, indicating elemental Al), when the Al is supposed to be bound with Ca as calcium aluminates (CaO.nAl2O3). And there is no evidence of Zn or Cr after the soak, suggesting that the pre-soak signals (described by Harrit as "tiny blips") were surface contamination. In Figure (17) there is very high Al and very low Mg. Harrit says, in his reply to Denis Rancourt, that they "performed a background study where the SEM beam hit the pedestal directly" and found it was an Al-Mg alloy, not pure Al. They must have compared the Figure (17) Al:Mg ratio with that which they found for the "alloy", and concluded that the tiny amount of Mg in relation to Al was too low to indicate a false signal from the sample holder. And Harrit says the gray layer acted as a control because it never picked up Al from the sample holder - as shown in Figure (6). Harrit says "magnesium was never observed" - not strictly true, since there is the tiny amount in Figure (17). But there is so little of it, and no post-soak evidence of Zn or Cr, that his points remain valid. In Tnemec primer, there should be significant Zn, Cr, Ca and Mg (from talc). Even the Ca seems to have vanished after the soak, when there was so much of it before. And contamination from wallboard seems the most likely source of the pre-soak sulfur - and would also account for the Ca. I suspect the MEK chip, and the primer from WTC2 floor 55, are a third primer.